Main Visual

360° Tire View

Fierce Fearless The Boldest FIT yet

X FIT AT2

No compromises.

On-road or off-road, the X FIT AT2 delivers dependable performance that keeps you safe and ready for adventure.

Engineered for confident control across all terrains, it features a bold and aggressive design that stands out wherever you go.

- X FIT AT2

- X FIT AT

-

Mileage

115 -

Wet Braking

102 -

Wet

104

Handling -

Dry Braking

107 -

Dry Handling

102 -

Noise

102 -

Ride

100

Features

-

1

Distinctive and aggressive appearance

-

2

Exceptional durability across rough and demanding terrains

-

3

All-weather capability ensures reliability in any seasons

-

4

Improved tread wear for extended mileage

-

3PMSF

3PMSF : 3 Peak Mountain Snowflake

-

M+S

M + S : Mud + Snow

Property/Benefit/Warranty

Property

-

Off Road

-

Dry

-

Wet

-

Snow

Benefit

-

Durability

-

Braking

-

Noise

-

Traction

Warranty

spec

Available Sizes

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037236 | 235/75R15 | 109T | XL | 4 | BSW | 28.9 | 9.3 | 698 | 12.6 | 32.9 | 2271 | 50 | 680 A B | - | 6.5 | 6.0-8.0 |

| 2022553 | 30X9.50R15LT | 104S | C | 6 | BSW | 29.5 | 9.4 | 684 | 15.1 | 37.6 | 1985 | 50 | - | - | 7.5 | 6.0-8.0 |

| 2022527 | 31X10.50R15LT | 109S | C | 6 | BSW | 30.6 | 10.6 | 659 | 15.1 | 40.7 | 2270 | 50 | - | - | 8.5 | 7.0-9.0 |

| 2022554 | 33X12.50R15LT | 108S | C | 6 | BSW | 32.5 | 12.5 | 621 | 15.7 | 62.9 | 2205 | 35 | - | - | 10 | 8.0-10.5 |

| 2022555 | 35X12.50R15LT | 113R | C | 6 | BSW | 34.5 | 12.5 | 585 | 15.7 | 57.8 | 2535 | 35 | - | - | 10 | 8.0-10.5 |

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037521 | 235/70R16 | 106T | - | 4 | BSW | 29 | 9.4 | 695 | 12.6 | 32.2 | 2094 | 51 | 680 A B | - | 7 | 6.0-8.0 |

| 1037526 | 245/75R16 | 115T | XL | 4 | BSW | 30.5 | 9.8 | 661 | 12.7 | 37.2 | 2679 | 50 | 680 A B | - | 7 | 6.5-8.0 |

| 1037232 | 265/70R16 | 116T | XL | 4 | BSW | 30.6 | 10.7 | 659 | 13.0 | 37.4 | 2756 | 50 | 680 A B | - | 8 | 7.0-9.0 |

| 1037235 | 265/75R16 | 116T | - | 4 | BSW | 31.7 | 10.5 | 636 | 13.0 | 38.4 | 2756 | 51 | 680 A B | - | 7.5 | 7.0-9.0 |

| 2022541 | LT215/85R16 | 115/112R | E | 10 | BSW | 30.4 | 8.8 | 663 | 15.1 | 39.2 | 2680/2470 | 80 | - | - | 6 | 5.0-7.0 |

| 2022526 | LT225/75R16 | 115/112R | E | 10 | BSW | 29.3 | 9 | 688 | 15.1 | 37.7 | 2680/2470 | 80 | - | - | 6 | 6.0-7.5 |

| 2022556 | LT235/85R16 | 120/116R | E | 10 | BSW | 31.7 | - | 636 | 15.1 | 45.0 | 3042/2778 | 80 | - | - | 6.5 | 6.0-7.5 |

| 2022524 | LT245/75R16 | 120/116R | E | 10 | BSW | 30.5 | 10.1 | 661 | 15.1 | 41.5 | 3042/2778 | 80 | - | - | 7 | 6.5-8.0 |

| 2022523 | LT265/75R16 | 123/120S | E | 10 | BSW | 31.6 | 10.8 | 638 | 15.1 | 46.9 | 3415/3085 | 80 | - | - | 7.5 | 7.0-9.0 |

| 2022537 | LT285/75R16 | 126/123R | E | 10 | BSW | 33 | 11.4 | 611 | 15.7 | 56.7 | 3750/3415 | 80 | - | Y | 8 | 7.5-9.5 |

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037519 | 225/65R17 | 102H | - | 4 | BSW | 28.5 | 9 | 708 | 12.1 | 28.9 | 1874 | 51 | 680 A B | - | 6.5 | 6.0-8.0 |

| 1037520 | 235/65R17 | 108H | XL | 4 | BSW | 29.1 | 9.4 | 693 | 12.2 | 31.2 | 2205 | 50 | 680 A B | - | 7 | 6.5-8.5 |

| 1037522 | 235/75R17 | 109T | - | 4 | BSW | 30.9 | 9.3 | 653 | 12.6 | 34.6 | 2271 | 51 | 680 A B | - | 6.5 | 6.0-8.0 |

| 1037524 | 245/65R17 | 111T | XL | 4 | BSW | 29.5 | 9.8 | 684 | 12.3 | 35.6 | 2403 | 50 | 680 A B | - | 7 | 7.0-8.5 |

| 1037525 | 245/70R17 | 110T | - | 4 | BSW | 30.6 | 9.8 | 659 | 12.7 | 36.1 | 2337 | 51 | 680 A B | - | 7 | 6.5-8.0 |

| 1037527 | 255/65R17 | 110T | - | 4 | BSW | 30.1 | 10.2 | 670 | 12.5 | 36.6 | 2337 | 51 | 680 A B | - | 7.5 | 7.0-9.0 |

| 1037528 | 255/70R17 | 116T | XL | 4 | BSW | 31.1 | 10.2 | 648 | 12.8 | 37.1 | 2756 | 50 | 680 A B | - | 7.5 | 6.5-8.5 |

| 1037514 | 255/75R17 | 115T | - | 4 | BSW | 32 | 10 | 630 | 12.8 | 38.7 | 2679 | 51 | 680 A B | - | 7 | 6.5-8.5 |

| 1037229 | 265/65R17 | 116T | XL | 4 | BSW | 30.6 | 10.7 | 659 | 12.6 | 39.5 | 2756 | 50 | 680 A B | - | 8 | 7.5-9.5 |

| 1036875 | 265/70R17 | 115T | - | 4 | BSW | 31.6 | 10.9 | 638 | 12.7 | 24.7 | 2679 | 51 | 680 A B | - | 8 | 7.0-9.0 |

| 2022518 | 35X12.50R17LT | 125S | E | 10 | BSW | 34.6 | 12.5 | 583 | 15.7 | 64.6 | 3640 | 65 | - | Y | 10 | 8.0-10.5 |

| 2022543 | 37X12.50R17LT | 128S | E | 10 | BSW | 36.6 | 12.9 | 551 | 15.7 | 66.8 | 3970 | 65 | - | Y | 10 | 8.0-10.5 |

| 2022536 | LT235/80R17 | 120/117R | E | 10 | BSW | 31.8 | 9.4 | 634 | 15.1 | 42.9 | 3085/2835 | 80 | - | - | 6.5 | 6.0-8.0 |

| 2022557 | LT245/70R17 | 119/116S | E | 10 | BSW | 30.6 | 9.8 | 659 | 15.1 | 45.4 | 3000/2755 | 80 | - | - | 7 | 6.5-8.0 |

| 2022521 | LT245/75R17 | 121/118S | E | 10 | BSW | 31.5 | 10 | 640 | 15.1 | 45.5 | 3195/2970 | 80 | - | - | 7 | 6.5-8.0 |

| 2022233 | LT265/70R17 | 123/120S | E | 10 | BSW | 31.6 | 11 | 638 | 15.7 | 46.9 | 3415/3085 | 80 | - | - | 8 | 7.0-9.0 |

| 2022525 | LT285/70R17 | 126/123S | E | 10 | BSW | 32.8 | 11.7 | 615 | 15.7 | 61.3 | 3750/3415 | 80 | - | Y | 8.5 | 7.5-9.5 |

| 2022560 | LT315/70R17 | 126/123S | E | 10 | BSW | 34.4 | 12.7 | 586 | 15.7 | 60.3 | 3750/3415 | 65 | - | Y | 9.5 | 8.0-10.5 |

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037523 | 245/60R18 | 105H | - | 4 | BSW | 29.6 | 9.8 | 681 | 12.3 | 34.7 | 2039 | 51 | 680 A B | - | 7 | 7.0-8.5 |

| 1037529 | 255/70R18 | 113T | - | 4 | BSW | 32.1 | 10.2 | 628 | 12.8 | 38.7 | 2535 | 51 | 680 A B | - | 7.5 | 6.5-8.5 |

| 1037516 | 265/60R18 | 110T | - | 4 | BSW | 30.5 | 10.7 | 661 | 12.6 | 37.8 | 2337 | 51 | 680 A B | - | 8 | 7.5-9.5 |

| 1037234 | 265/65R18 | 116T | XL | 4 | BSW | 31.5 | 10.7 | 640 | 12.6 | 38.9 | 2756 | 50 | 680 A B | - | 8 | 7.5-9.5 |

| 1037517 | 265/70R18 | 116T | - | 4 | BSW | 32.6 | 10.7 | 619 | 13.0 | 40.8 | 2756 | 51 | 680 A B | - | 8 | 7.0-9.0 |

| 1037231 | 275/65R18 | 116T | - | 4 | BSW | 32.1 | 11 | 628 | 12.7 | 40.7 | 2756 | 51 | 680 A B | - | 8 | 7.5-9.5 |

| 2022561 | 33X12.50R18LT | 122S | F | 12 | BSW | 32.5 | 12.5 | 621 | 15.7 | 68.0 | 3305 | 80 | - | Y | 10 | 8.5-11.0 |

| 2022519 | 35X12.50R18LT | 128R | F | 12 | BSW | 34.6 | 12.7 | 583 | 15.7 | 70.8 | 3970 | 80 | - | Y | 10 | 8.5-11.0 |

| 2022542 | 37X12.50R18LT | 128R | E | 10 | BSW | 36.5 | 13.1 | 553 | 15.7 | 72.8 | 3970 | 65 | - | Y | 10 | 8.0-10.5 |

| 2022538 | LT265/70R18 | 124/121S | E | 10 | BSW | 32.6 | 11 | 619 | 15.1 | 49.7 | 3525/3195 | 80 | - | - | 8 | 7.0-9.0 |

| 2022548 | LT275/65R18 | 123/120S | E | 10 | BSW | 32.1 | 11 | 628 | 15.1 | 57.8 | 3415/3085 | 80 | - | Y | 8 | 8.0-9.5 |

| 2022549 | LT275/70R18 | 125/122S | E | 10 | BSW | 33.3 | 11.1 | 606 | 15.1 | 58.2 | 3640/3305 | 80 | - | Y | 8 | 7.0-9.0 |

| 2022545 | LT285/65R18 | 125/122S | E | 10 | BSW | 32.6 | 11.7 | 619 | 15.7 | 61.7 | 3640/3305 | 80 | - | Y | 8.5 | 8.5-10.0 |

| 2022540 | LT295/70R18 | 129/126S | E | 10 | BSW | 34.3 | 11.8 | 588 | 15.7 | 66.4 | 4080/3750 | 80 | - | Y | 8.5 | 7.5-10.0 |

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037515 | 265/50R20 | 111T | XL | 4 | BSW | 30.5 | 10.9 | 661 | 11.6 | 39.7 | 2403 | 50 | 680 A B | - | 8.5 | 7.5-9.5 |

| 1037233 | 275/55R20 | 117T | XL | 4 | BSW | 31.9 | 11.2 | 632 | 12.2 | 41.4 | 2833 | 50 | 680 A B | - | 8.5 | 7.5-9.5 |

| 1037230 | 275/60R20 | 115T | - | 4 | BSW | 33 | 11 | 611 | 12.7 | 44.1 | 2679 | 51 | 680 A B | - | 8 | 7.5-9.5 |

| 2022516 | 33X12.50R20LT | 119R | F | 12 | BSW | 32.6 | 12.6 | 619 | 15.7 | 66.0 | 3000 | 80 | - | Y | 10 | 8.5-11.0 |

| 2022515 | 35X12.50R20LT | 125R | F | 12 | BSW | 34.5 | 12.7 | 585 | 15.7 | 71.7 | 3640 | 80 | - | Y | 10 | 8.5-11.0 |

| 2022517 | 37X12.50R20LT | 126R | E | 10 | BSW | 36.6 | 12.5 | 551 | 15.7 | 75.8 | 3750 | 65 | - | Y | 10 | 8.5-11.0 |

| 2022558 | LT265/60R20 | 121/118R | E | 10 | BSW | 32.5 | 10.7 | 621 | 15.1 | 54.1 | 3195/2910 | 80 | - | - | 8 | 8.0-9.5 |

| 2022514 | LT275/65R20 | 126/123S | E | 10 | BSW | 34.2 | 11 | 590 | 15.1 | 63.0 | 3750/3415 | 80 | - | Y | 8 | 8.0-9.5 |

| 2022559 | LT285/55R20 | 122/119R | E | 10 | BSW | 32.4 | 11.7 | 622 | 15.7 | 61.6 | 3305/3000 | 80 | - | Y | 9 | 8.5-10.0 |

| 2022539 | LT285/60R20 | 125/122S | E | 10 | BSW | 33.5 | 11.4 | 602 | 15.7 | 63.0 | 3860/3525 | 80 | - | Y | 8.5 | 8.5-10.0 |

| 2022562 | LT305/55R20 | 125/122S | F | 12 | BSW | 33.2 | 12.4 | 607 | 15.7 | 68.6 | 3640/3305 | 80 | - | Y | 9.5 | 9.0-11.0 |

Material Code |

Size |

LI&SS |

Load Range |

Ply Rating |

Sidewall Color |

Overall Diameter (in) |

Overall Width (in) |

Revs Per Mile |

Tread Depth (/32in) |

Weight (lbs) |

Max. Load Single / Dual (lbs) |

Max. Pressure (psi) |

UTQG |

3ply |

Recommended Rim Width |

Rim Width Range |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1037518 | 285/45R22 | 114H | XL | 4 | BSW | 32.1 | 11.2 | 628 | 11.8 | 41.0 | 2601 | 50 | 680 A B | - | 9.5 | 9.0-10.5 |

Wherever the road takes you

All-terrain tire for Pickups and SUVs

Aggressive and Bold Appearance

The Laufenn X FIT AT2 combines rugged, all-terrain performance with a bold, aggressive design.

Built to give you the confidence to conquer any road, it’s the perfect companion for every adventure.

-

Distinctive Design

Bold side blocks with a rugged, irregular design form a unified,

solid structure (4in1) that enhances the powerful off-road look while providing grip where it counts. -

Lettered for Impact

3D sidewall lettering enhances visual harmony while reinforcing Laufenn’s unique brand identity.

-

Cohesive Look

Integrated shoulder blocks connect the tread and sidewall,

delivering a cohesive look and added traction for improved handling.

Durability

The X FIT AT2 delivers exceptional durability with consistent performance across rough and demanding terrains.

-

Durability

-

Off Road

-

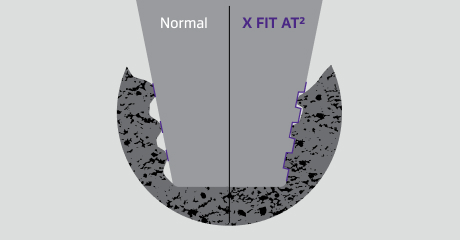

Enhanced Robustness

With its 3 ply construction, the X FIT AT2 delivers reinforced strength and durability, offering enhanced confidence in harsh conditions.

* Available in select sizes

-

Off Road Protection

Offset shoulder blocks enhance protection against sharp rocks and off-road hazards, while their staggered layout improves both durability and traction.

-

Rim Protectors

A rim protector designed into the tire’s bead section helps to prevent external impact damage that can occur when driving in rugged terrains and also helps protect vehicle wheels.

Long-Lasting Adventure

The X FIT AT2 delivers reliable on- and off-road performance with long-lasting tread life.

-

Wear Life

-

Durability

-

Off Road

-

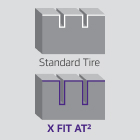

Increased Tread Wear

Laufenn's compound has improved wear performance by

applying high-abrasion carbon black. X FIT AT2 compromise that long lasting adventure.X FIT AT2 115%X FIT AT 100% -

Maintain Grip with Deep Sipes

A 2-step deep sipe design helps to maintain both on and off-road performance throughout the life of the tire.

-

Prevent Irregular Wear

Optimized tread blocks maintain balanced stiffness, reducing irregular wear and extending tread life. The X FIT AT2 ensures consistent contact even on uneven terrain.

X FIT AT2

X FIT AT2

Conventional

Conventional

All Weather Performance

From dry roads to snowy trails, the X FIT AT2 delivers year-round performance with 3PMSF certified winter capability.

-

3PMSF

3PMSF : 3 Peak Mountain Snowflake

-

M+S

M + S : Mud + Snow

-

Dry

-

Wet

-

Snow

-

Traction

-

Ensuring Winter Season

3D sipes enhance winter performance and driving stability by reducing block movement, while 3PMSF certification ensures reliable traction in severe winter conditions.

-

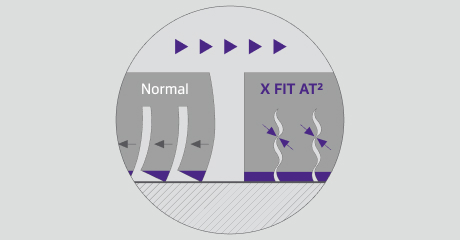

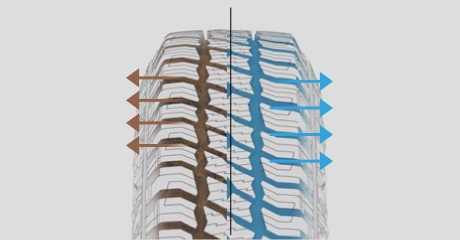

Control on Soaked Terrain

Directional and lateral grooves help prevent hydroplaning and efficiently evacuate water and mud, while the high-hysteresis compound ensures confident performance on wet roads.

-

Enhanced Traction

Stepped shoulder edges improve traction and grip on both on- and off-road surfaces while also enhancing dry performance.

Dual Ride Experience

The X FIT AT2 delivers a quiet and comfortable ride on any surface,

while also providing precise steering control for a dynamic driving experience.

-

Noise

-

Handling

-

Traction

-

Dynamic Driving

Multi-directional grooves and sipes provide traction in all directions and enable dynamic driving.

-

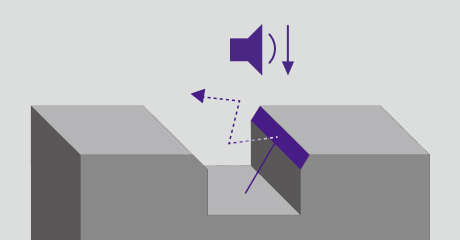

Reduced Impact Noise

Chamfered block edges further minimize impact noise on all terrains.

-

Noise-optimized Tread Design

The X FIT AT2 features an optimized tread pitch sequence developed through advanced noise simulation, reducing road noise for a quieter, more comfortable ride.

Warranty

Warranty

Learn MoreGallery

Video

Tire guide / Care guide

Tire guide

- Tire structure

- Tire sidewall

- Sizes & specs

- Load & speed

Tire structure

Tread, shoulder, sidewall, bead, carcass, belt, inner liner, and other components are structurally connected to complete the scientific structure of a tire.

Tread (the part that has direct contact with the road surface)

The tread consists of a thick layer of rubber which comes into direct contact with the road surface. It is highly resistant to fracture and shock in order to protect the carcass and belt located in the tire’s interior. Also, rubber with strong anti-inner abrasion features is used to increase the tire’s driving lifespan.Shoulder (the shoulder of the tire)

Located between the tread and sidewall, the shoulder is the thickest part in a tire. Because of this, the shoulder is designed to quickly and easily dissipate heat that accumulates inside the tire while driving.Sidewall (the side of the tire)

Located between the tire’s shoulder and bead, the sidewall protects the carcass on the inside and provides a comfortable riding experience due to its flexibility during driving. Also, the type of tire, size, structure, tread pattern, manufacturer, brand name and other detailed information are marked on the sidewall.Bead (the part that is in contact with the rim)

The bead wraps around the end of the cord and fixes the tire to the rim. It is made up of various parts including the bead wire, core, rubber and flipper. In general, the rim is slightly tightened so in the case of sudden reduction of air pressure while driving, the tire will not become unfastened from the rim.Carcass (the framework of the tire)

The carcass is the framework of the tire, the most important part. The carcass refers to all layers made up of tire cord. It absorbs the tire’s internal air pressure, weight and shock.Breaker or belt (the layer in between the tread and carcass)

The breaker is a cord layer placed in between the tread and carcass to protect the carcass. It absorbs external shock and prevents splintering or injury to the tread from coming into direct contact with the carcass. At the same time, the breaker prevents the separation of the rubber layer and carcass. The belt is a strong reinforcement layer located in the circumference in between the tread and carcass in radial tires. The belt’s functions are similar to those of the breaker but it also reinforces the strength of the tread by firmly tightening the carcass.Inner liner

The inner liner substitutes for the tube in the tire’s interior and consists of rubber layers with low air permeability. The rubber layer generally consists of butyl, synthetic rubber or polyisoprene type. The main function of the inner liner is to hold high-pressure air inside.Tire sidewall

A tire’s sidewall protects the carcass on the inside and provides a comfortable riding experience due to its flexibility during cornering. Also, the type of tire, size, structure, tread pattern, manufacturer, brand name, and other detailed information are marked on the sidewall.

DOT (Department of transportation)

tire size

tire size notation is dependent on vehicle type but primarily consists of symbols and numbers denoting tire width, aspect ratio, diameter, load index and speed symbol that indicate tire performance.Safety warning

This indicates important information related to tire use.Place of origin

This indicates the region where the tire was manufactured.Size & specs

The selection criteria for tires change depending on the type of vehicle you own and your style of driving. For a pleasurable driving experience, it is important to take these factors into consideration when selecting an appropriate Laufenn tire product.

tire section width

Distance (mm) in a straight line between the sidewalls fitting to rim with standard air pressure and without loads.tire section height

Half of the distance which is the difference between the tire’s outer diameter and rim diameter.Aspect ratio

The ratio of section height to section width.*Aspect ratio = (Height) / (Width) X 100

Rim diameter

The distance between the rim bases in contact with the rim flange (almost identical to the tire’s interior diameter).tire overall diameter

Outer diameter of tire fitting to rim with standard air pressure and without loads.Load & speed

The symbol that shows a tire's performance level consists of two parts: tire performance is marked by load index (LI) and speed symbol (SS). LI refers to the maximum load that one tire can support, and SS refers to the maximum speed that a tire can handle.

Load index

Load index is a numerical code stipulating the maximum load each tire can carry. For example, if the load index is 100, it means that a tire can carry a load up to 800kg.Speed symbol

Speed symbol indicates the maximum speed at which the weight (with the exception of weight when speed is equal to or exceeds 210 km/h) designated by the manufacturing company can be supported by the tire.

Care guide

- Tire pressure

- Maintenance

- Rotation

- Balance

- Wheel alignment

- Replacement

tire pressure

The tire inflation pressure is directly related to safety. Therefore, tire pressure must be checked regularly, and proper maintenance can prolong the lifespan of the tires. Learn about the importance of tire inflation pressure and how to check the pressure of your tires.

Importance of tire pressure

- Optimum air pressure should be maintained to ensure safety, driving performance, tire life and fuel cost.- tires have been known to lose up to one psi in a month (psi: pound per square inch) Therefore, it is important to check all tires, even the spare, at least once a month or before a long trip.

Recommended interval

tire pressure should be checked every month.Checking for optimum tire pressure

Laufenn tire recommends you to check your tire pressure once in a month.The optimum air pressure level for your tire can be found on the inner side of the car door, inside the fuel cap or in the car manual (the location of the sticker can vary according to country).

DO NOT compare your inflation pressure to its maximum pressure marked on the tire’s sidewall.

How to check tire pressure

1. Purchase a certified air pressure gauge or take your vehicle to a nearby service centre (or gas station) for a check-up.2. tires must be checked in a “cold” state (at least three hours after driving).

3. Insert the gauge into the valve.

4. Compare the measured air pressure level with the level listed on the car door.

- If the measured figure is higher, release air until the figure matches what is listed on the car door.

- If the measured figure is lower, insert more air until the figure matches what is listed on the car door.

Maintenance

tire wear directly affects the driver’s safety and the performance of the vehicle. It is essential for the driver to be well-informed about how to check for tire wear regularly.

Importance of checking for tire wear

The deeper the groove, which is on the surface of the tire, the more grip a tire will have. You can prevent danger of unexpected accidents by checking for tire wear on a regular basis.Recommended interval between check-ups

Laufenn tire recommends that you check for tire wear once each month. Also, make sure to do a check once more after long distance travel.Checking for tire wear with tire tread wear indicator

You can check for the depth of the groove by using a tire tread depth gauge or by observing the tread wear indicator on the side of the tire. To ensure optimum safety and performance, tires should be replaced when the tire groove wears below 2mm to 3mm.Rotation

Periodic rotation prevents uneven wear, prolonging the life of your tires. Learn about the importance of tire rotation and how to rotate them.

The importance of tire rotation

Periodic tire rotation helps extend the life of your tires and improves performance level. For safe driving and saving money, please refer to the rotation method below.When to rotate your tires

In general, it is best to rotate tires every six months or 10,000km. Changing tire position to an alternative position ensures even wear and long life of the tire.Balance

tire balance must be checked if there is unexpected vibration or noise from a tire. Learn about the importance of tire balance, which is necessary for a comfortable driving experience, and when to inspect a balance.

The importance of tire balance

tire balancing is a process of compensating for the weight of the tire and wheel after assembly. If not properly balanced, it increases vibration and causes stress to your vehicle.When to inspect for tire balance

If you feel a vibration from a tire, visit a mechanic. A mechanic will attach a balancing weight to the exterior or interior of the wheel to counteract centrifugal forces acting on the heavy areas when the wheel is turning.How to balance tire and wheel

To balance the tire and wheel assembly, a balance weight can be used when a certain spot is lighter or heavier than it should be.Wheel alignment

To prevent vibration, skidding, noise and wear, wheel alignment inspection is necessary. Learn about useful information regarding wheel alignment and how to perform an inspection.

The importance of wheel alignment

The purpose of wheel alignment is to adjust front-wheel handling while driving. If wheel alignment is off, tire life is shortened while car and mileage performance also decrease.When to check wheel alignment

Laufenn tire recommends inspecting wheel alignment every year or every 20,000km. The inspection is required:- after a car accident.

- after tire replacement.

- when there is uneven wear on a shoulder.

- when the steering wheel is unstable and/or vibrating

- when riding is uncomfortable or fuel efficiency gets worse

Replacement

In order to ensure a safe and comfortable ride, it’s strongly recommended that all drivers know when and how to replace tires.

The importance of tire replacement

Timely replacement of the tire is critical for driver safety and also influences vehicle lifespan and performance.When to replace a tire

- In case of severe tire erosion.- In case repair is impossible due to tire puncture.

How to replace a tire

In the case of a damaged tire and wheel, professional consultation is recommended. tire replacement should only be done by a trained and highly experienced technician.Tips for tire replacement

- It is the best to replace two tires on one axle at the same time.- The replacement of only one tire of the two tires on the same axle usually causes to unbalance the vehicle.

Loading...